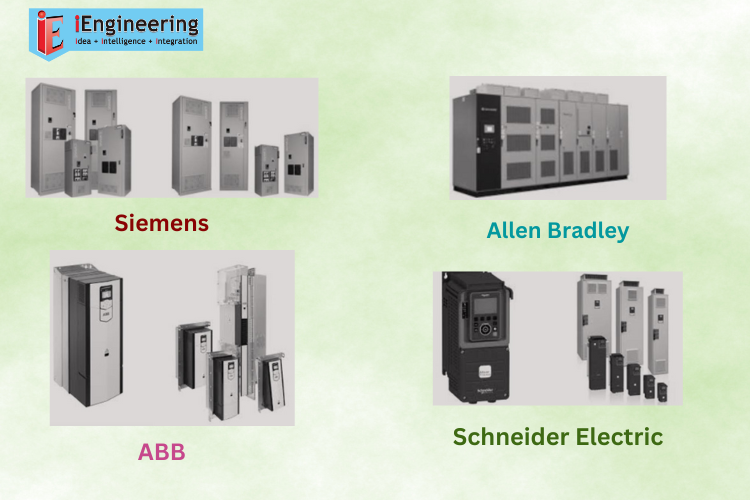

VSD – Variable Speed Drives

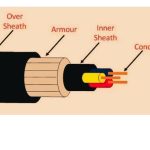

Electric motors are crucial to the operations and activities of our daily lives. They require the corresponding quantity of electric energy in order to perform their function of generating power and velocity, if the power or velocity is too high or low technical control will be used to slow down the transfer or control the output, wasting a lot of energy and resources. The motor’s frequency must be precisely aligned with the process’ needs. Without a more effective method of speed control, a lot of energy is wasted.

iEngineering VSDs constantly monitor, regulate, and more precisely manage the entire network, to increase the performance and efficiency of industrial motor systems.

Factors to consider when purchasing variable speed drives to boost energy efficiency in electrical equipment.

Enhanced operational performance

The mechanism operated by drives can be automated, eliminating the need for manual labor and saving on labor expenses.

Reductions in electricity costs

By operating the motors at rated power, variable speed drives utilize only the necessary amount of energy, reducing the drive system’s energy usage.

Savings on capital investments

In pump and fan applications, the VSD investment can quickly pay for itself after installation due to the instant decrease in electrical consumption.

Cost savings on repairs and replacement parts

Drives provide for the decrease the mechanical system stress during startup and operation, resulting in an extended equipment lifespan.

This kind of significant improvement can be made in both big commercial operations and small facilities, you can estimate the potential energy and cost savings realized by using iEngineering low voltage AC variable speed drive control compared to conventional methods like valves and switches.

Which one is better VSD or VFD?

Despite many similarities between variable frequency drives and variable speed drives, you might be uncertain of which option is appropriate for your business model. Both tools can increase the effectiveness of your motors by reducing excessive power usage and cost-savings.

At 82% efficiency, a variable speed drive performs now at peak. Therefore, it is advised in circumstances when your motor will start, operate at a high standard, and then stop. While on, it can reduce energy consumption, but to maintain efficiency, it must run at a reasonably high level.

In contrast, if your motor operates continuously, a variable frequency drive is ideal. Your motor can be used at a capacity lower than 80%.

For more information please visit: https://ieng.tech/vsd-variable-sequence-drives/

If you have any questions or enquiries, kindly feel free to email us ferdina@iengaust.com.au or anandhi@iengaust.com.au