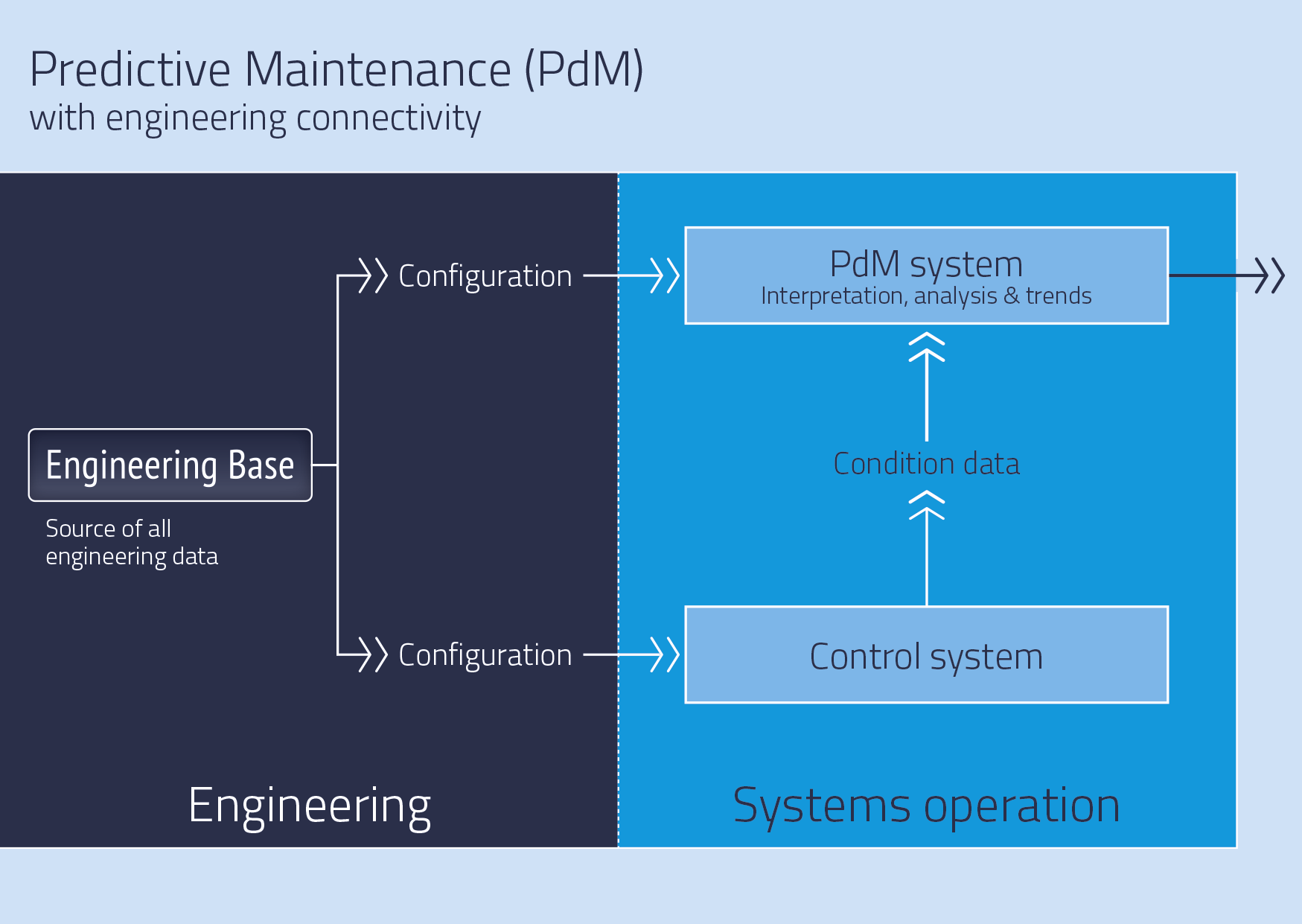

Plant failures are expensive. Unforeseen repairs in plant operations always cost far too much time and unplanned downtimes can result in huge losses. Predictive maintenance (PdM) is intended to help avoid potential system failures by means of prompt predictions so that costs relating to maintenance, service, and of course downtime are minimized as far as possible.

We are glad to share that the system platform Engineering Base (EB) is the only software system that has been able to intelligently network engineering with a PdM tool due to its architecture. EB can be closely linked to high-performance analysis applications for PdM.

The advantages:

• Highest level of consistency and enormous saving of time due to a central source for all engineering data

• Mapping option for abstract objects (signals/interpretations) in EB’s data model creates conditions for a consistent link to predictive maintenance (PdM)

• Automatic assignment of live plant data to engineering data instead of manual processing of thousands of signals

• No separate “feeding” of the PdM system by different departments using laboriously prepared engineering data.

For Enquiries kindly contact: aparna@ieng.tech

For more information please visit: https://ieng.tech/