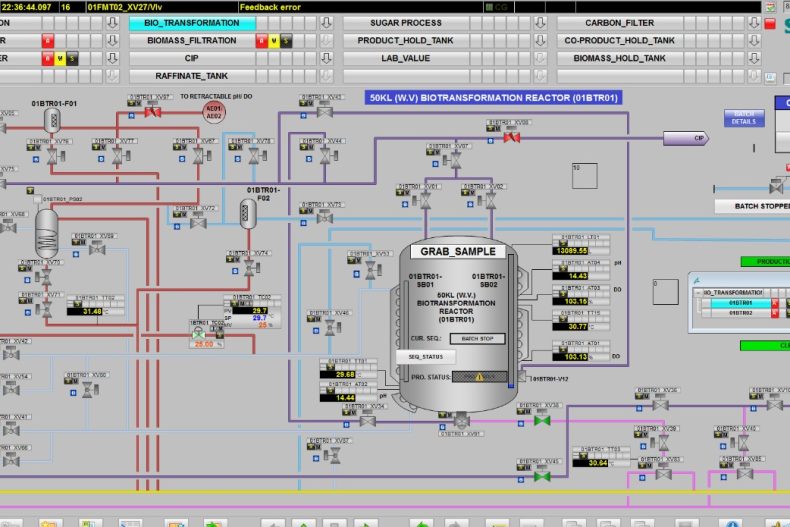

SCADA (supervisory control and data acquisition)

SCADA (supervisory control and data acquisition) is a type of software application used to regulate industrial processes by acquiring data in real-time from remote places and regulating equipment and conditions. SCADA gives enterprises the tools they need to make and implement data-driven choices about their industrial processes.

SCADA, one of the most widely used types of industrial control systems, can manage practically any type of industrial operation.

SCADA systems are made up of both hardware and software components. The hardware collects and feeds data into field controller systems, which pass the data to other systems, which process and show it to a human-machine interface (HMI) in real-time. SCADA systems record and log all events for the purpose of reporting process status and faults. SCADA applications sound alarms when situations become unsafe.

SCADA systems reduce reaction times, lower task overheads, and maximize the efficiency of the Industrial assets.

SCADA- SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA) are developed for visualization, operation & control of discrete assembly line, Large machines, process, process flows, and plant Levels.

SCADA is used by many industries for the following purposes:

- Centralized /Decentralized monitoring & control of processes & Machines.

- Web-Based Remote Monitoring & Control of processes & Machines.

- Server-Client architecture for large applications.

- Process/plant Historian

- Continuous Data archiving

- Batch Control

- MIS Reporting for Management Analysis, Review and control

- Data Analysis

- Maintenance Station-Preventive, Proactive Maintenance Management, Time Based Maintenance

- Alarm, Fault, Event Logging

- Trending of various process Data

- Production Monitoring & Control

- Raw Materials Monitoring & Control

- Rejection Analysis

- Track & Trace of Batches

We are providing complete solutions from a small-scale to Large scale application

- Profibus PA for Field Instruments connectivity with PLC

- Foundation Field Bus for Field Instruments connectivity with PLC

- HART Communication for Field Instruments connectivity with PLC

- MODBUS RTU

- MODBUS TCP/IP

- Ethernet TCP/IP

- Profibus DP

- Profibus PA

- Profinet

- ASi

- CANOpen

- DNP3

- IEC61850

- IEC60870-5-101

- IEC60870-5-104

- EtherCAT

- BACnet

- LON

- OPC A&E

- OPC DA

- OPC UA

We work with the following OEM’s SCADA Ranges at present:

| OEM | Series |

| Siemens | Simatic WinCC |

| Rockwell | Factory Talk view |

| ABB | Compact HMI, 800XA |

| Wonderware | InTouch |

iEngineering provides complete Automation solutions for SCADA control for MORANBAH

Supervisory control and data acquisition (SCADA) is a system of software and hardware elements that allows industries to Monitor, gather, and process real-time data. Directly interact with devices such as sensors, valves, pumps, motors, and more through human-machine interface (HMI) software. Ventilation monitoring and control in mines are becoming an integral part of the habitual activity for maintaining the health and safety of mine workers and technicians. We give potential real-time monitoring and control solutions for detecting and reducing the temperature, pressure variations, flow rates, speed control, and voltage variations mine fires, and dust in site. All SCADA Solution components need to be nondisruptive in interaction with one another, particularly if there is a large remoteness between any component. Instantaneous response and access to replace components are an integral part of this system design. The design team of us employ proven techniques to ensure the best implementation strategy and the design is developed based on the client requirements. Our team has proven experience in designing and estimate the project structure as well as the ideas to develop the technologies required to fulfill customized solutions for MORANBAH mining project regarding vent fans

For more details, kindly visit this page https://ieng.tech/scada-supervisory-control-and-data-acquistion/

iEngineering has appreciated the long-term supports and love from the clients, which keep us moving forward continuously.

For more details or enquiries kindly reach us at anandhi@iengaust.com.au or ferdina@iengaust.com.au