The important parameters to consider while selecting power cables for installation are.

1. Voltage level: Voltage level needs to be considered.

1. Low voltage cable (0 to 1000V): Low voltage cables are used for industrial power installations in various fields like general industry, public installations, infrastructures, etc.

2. Distribution voltage cables (11kV,22kV): They are used in the distribution of electricity from electrical substations to Distribution transformers.

3. Sub Transmission and Transmission voltage cables (33kV,66kV, and 132kV): They are used to transport electricity from the generating plants to the electrical substations.

2. Load Current– A Load Current is the nominal current that passes from a power supply to the device or load. The power delivered electrically is the product of voltage and current in the circuit. Hence, the cross-section area of the cable should be sufficient to carry the maximum load current.

Total Load current(I) for 3 phases = kVA/1.732* Line-Line voltage

3. Short circuit current: The electricity will flow through a ‘short’ route and cause an electrical short circuit. It determines the minimum cross-sectional area of cable required.

A= I*T/K

I = Fault Current

T= Fault clearing time

K= Constant depends on cable material (XLPE OR PVC)

A= Cable cross-section area

4. Derating- The derating factor is applied to reduce the cable’s current carrying capacity based on the surrounding installation. Derating considers air temperature, soil temperature, cable depth, and Soil resistivity. So, need to upsize the cable to carry the nominal current.

5. Voltage Drop: It determines the reduction in voltage in an electrical circuit between the source and load. Voltage drop occurs at the load compared to the supply end. The Australian standard allows the voltage to drop by 5%. Generally, power utilities allow a 2.5% voltage drop.

To improve voltage drop upsize the cable or use the copper cable as a better conductor of electricity than Aluminium. Standards Australia issued AS 60038 in 2000 with 230/400 volts as the nominal voltage with a +10%, -6% range.

The formula for calculating Voltage drop is: Vd= Y x I x L

Y= value from tables in mV/A/m

L=Length of cable

I= Load Current

For example- The load current is 100A transmitted over a route length of 150m, 35mm²cable at 75℃ for three phases.

Voltage drop = Y x I x L

= 1.12 mV/A/m x 100A x 150m

= 16.8 volts (OK for Australian Standard)

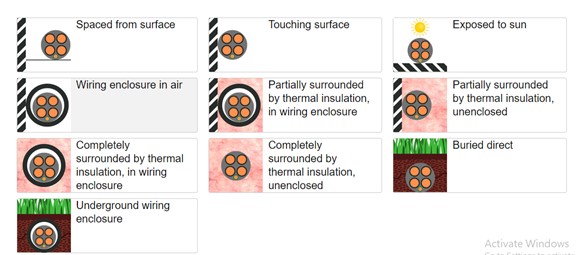

6. Laying method: Here are different methods of laying cables as below:

- Spaced from the surface

- Touching surface

- Exposed to the sun

- Wiring enclosure in air

- Partially surrounded by thermal insulation, in the wiring enclosure

- Partially surrounded by thermal insulation unenclosed

- Completely surrounded by thermal insulation, in the wiring enclosure

- Completely surrounded by thermal insulation, in wiring unenclosed

- Buried direct

- Underground wiring enclosure

7. Bending radius: The cable bending radius is a measurement of the smallest radius of a cable that may be bent about without being harmed. The size of the cable, its structure, the kind of conductor, and the sheathing and insulation types used are all factors that influence the minimum bending radius. The minimum bend radius depends on the diameter of the cable and the type of cable. A material’s flexibility increases with decreasing bend radius.

8. Termination Kit: Termination kits are necessary for connecting cables to switchgear terminals, transformer terminals, poles, etc. The types of termination kits are heat-shrink type, cold-shrink type, and cable terminations.

9. Mechanical protection: Electrical cables are protected mechanically or electrically by cable coatings. SWA Steel Wire Armoured cables which having steel armored to withstand higher pulling loads. Electrical wire is protected and routed in a building or structure using an electrical conduit, Electrical Underground wiring Tape, and Underground Hard cable cover.

10. Degradation: There are a few factors that might cause the sheathing material to deteriorate, such as extreme heat (UV exposure) or cold, chemicals, environmental factors, weather, and sheath abrasion. As the insulated cores are no longer properly protected by the sheathing, all these conditions may eventually result in electrical failure and the need to do a renovation.