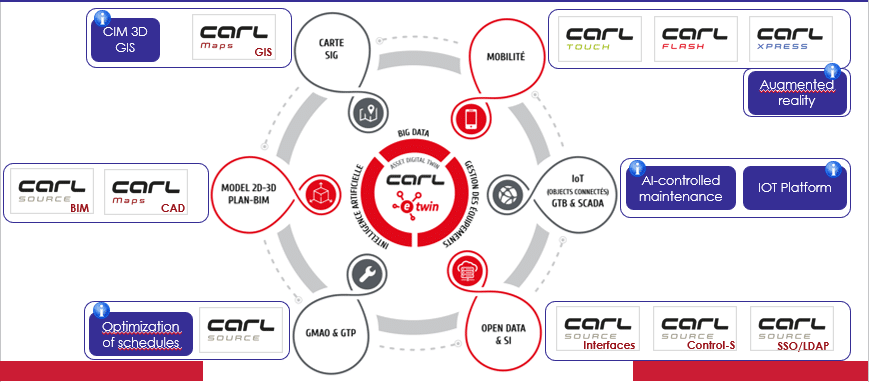

Digital Twin & IOT

Digital Twin & IOT {Predictive, Augmented Reality, AI etc}

To meet the challenges of Maintenance 4.0, our Technical Asset Management (TAM) and Computer-aided Maintenance Management Systems (CMMS) solution will evolve towards a unified technical platform for equipment management combining Business Processes, Big Data and Artificial Intelligence. This platform will bring new services such as : predictive maintenance of a complete installation, maintenance assisted by augmented reality, etc.

This universal concept can be adapted to all fields of activity, including industry, real estate, transport, healthcare, urban development, and more. An essential building block for projects relating to industry 4.0, smart buildings and smart cities.

These concepts call for a complete revolution in industrial and territorial management processes, and promise significant gains in terms of efficiency and flexibility, with numerous effects on the environment, organization of work, society and even the applicable legislation.

IOT - Internet of Things

With its capacity for the online, real-time connection between goods, places, and humans and its ability to transfer data over a wireless network to an Information System without human interaction, the Internet of Things (IoT) is shaking up companies in every sector of activity.

Thanks to the contribution of observation data sourced from the physical world, the fast and secure communication between physical goods and their digital existence (CMMS, digital mock-up), the IoT opens new perspectives:

- Optimization of maintenance performance: the right gesture at the right time and at the best cost.

- Energy management.

- Simulations and Forecasts.

IOT Platform

- Understand: when, why and how a malfunction occurs.

- Predict/anticipate the consequence(s) of the malfunction.

- Make recommendations as to the action(s) to be taken: maintain and/or configure equipment and/or take action on the environment (temperature, geographical position).

Augmented Reality

In concrete terms, the project entails equipping maintenance technicians with an augmented reality headset to facilitate maintenance work and enhance safety. Through a connection to the CARL Touch mobile application for field technicians, they have all the information they need for maintenance work, right before their eyes.

Using 3D vision, technicians can create a veritable “virtual workbench” anchored in the physical space where the work is to be performed: with a simple gesture, they can place the information needed for a technical operation within their field of view.

In real time, they can for instance:

- Display the 3 modelD of the machine being worked on;

- Display the list of operations to be performed and checked off;

- Produce an augmented report with full context, to avoid any transcription errors;

- Access remote assistance via Skype, sharing a live view with the hotline;

- Control data fully, to ensure faster and safer work.

The integration of the latest augmented reality technologies into CARL/Berger-Levrault’s maintenance management solutions demonstrates the technological and functional modularity of the CARL Source CMMS and the CARL Touch mobile application.

CARL/Berger-Levrault is currently working with partners and customers to test concrete examples of field work and support, so as to speed up the innovation process and consolidate its position as a major innovator in maintenance.