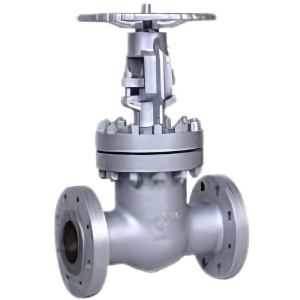

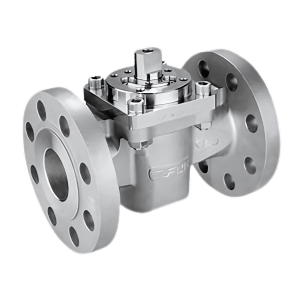

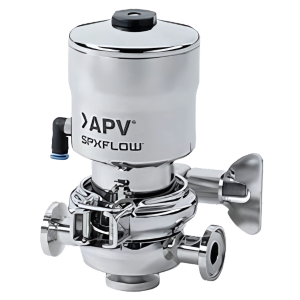

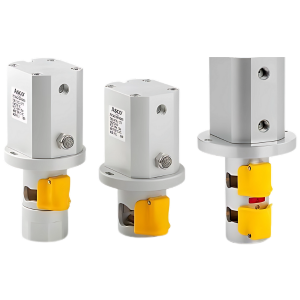

Welcome to iEngineering Group! With decades of expertise serving diverse industries across the Pacific Ocean region, we provide high-performance valves engineered for even the most demanding environments. From water treatment to oil and gas, our valves ensure efficiency, safety, and reliability in all applications.

At iEngineering Group, we are committed to delivering unparalleled quality and customized solutions. Here’s why clients trust us for their valve needs:

- Quality Assurance: Top-quality materials and advanced manufacturing techniques ensure optimal performance.

- Custom Solutions: Tailored valve solutions to meet exact project specifications.

- Industry Expertise: Decades of experience across various sectors with expert guidance on valve selection.

- Comprehensive Support: From product selection to post-installation service, we offer ongoing support.