- Practical Learning: Allows students to engage in real-time diagnostics and troubleshooting.

- Hands-on Training: Provides exposure to high-voltage battery management, motor control, and EV power electronics.

- Fault Simulation: Enables fault creation, detection, and resolution to enhance problem-solving skills.

- System Understanding: Helps trainees understand power distribution, regenerative braking, and thermal management.

- Industry Readiness: Equips students with necessary skills for careers in EV technology and automotive engineering.

- Realistic Environment: Uses original EV components for true-to-life training.

- Safety Assurance: Built-in protection mechanisms ensure safe handling of high-voltage systems.

- Comprehensive Analysis: Provides insight into the interaction between different EV subsystems.

- Modular Design: Supports different training levels, from basic diagnostics to advanced repair techniques.

- Adaptability: Can be customized for different vehicle models and training needs.

Types of EV Training Benches

The equipment is built using original BYD EV components, disassembled and re-engineered for educational purposes. It comprises five key training platforms: the BYD Qin EV power battery, motor drive, steering system, air conditioning system, and electrical appliances. These platforms enable real-time detection of static and dynamic vehicle data, fault code reading and clearing, simulated fault setting and recovery, and various hands-on training exercises. Designed for teaching, research, repair, operation, control, and inspection, this system serves as an essential tool for professional automotive training institutions specializing in new energy vehicle technologies.

Equipment 1 : BYD Qin EV Power Battery Training Platform.

The EV power battery management system training platform features a ternary lithium power battery pack assembly, high-voltage wiring harness, and a test panel, allowing students to easily identify and analyze battery components. By integrating with the drive motor training platform, students can study the high-voltage power-on logic of the battery pack, enhancing their understanding of battery operation, energy flow, and system diagnostics.

- Battery Type: High-voltage ternary lithium battery (DC 408.8V)

- Capacity: 53.1 kWh with an operational lifespan exceeding 2000 cycles

- BMS Features: Real-time monitoring of SOC, voltage, and temperature

- Safety Protections: Overcharge, short circuit, and thermal management

- Charging Compatibility: Supports slow and fast-charging analysis

The equipment frame is manufactured using a sheet metal process. The measuring panel is made of an 8mm aluminum-plastic plate, ensuring long-lasting color retention through a UV spraying process. The operation panel follows ergonomic design principles, making it user-friendly for students. The structure is resistant to fire, water, moisture, and corrosion. Additionally, the self-locking caster enhances maneuverability, providing flexibility, safety, reliability, and durability.

The power battery training platform is equipped with detection terminals, allowing students to analyze circuit signal characteristics using a multimeter and an oscilloscope.

The battery system comprises a power battery module, battery information collector, series cable, base, sealing cover, and battery sampling cable.

The training platform includes a main power switch along with various installation protection devices for enhanced safety.

The Battery Management System (BMS) features passive equalization and switch control protection against cell disconnection, short circuits, overvoltage, undervoltage, overcurrent, and overheating. It also supports CAN communication with the charger, manages vehicle charger operation, and estimates the State of Charge (SOC).

The cooling water pipe plug should be securely connected to the cooling line.

Equipment 2 : BYD Qin EV Motor Drive Training Platform.

The motor drive training platform features a permanent magnet synchronous drive motor assembly, power transmission shaft, steering knuckle assembly, electronic parking system, cooling system, brake pedal, accelerator pedal, gearshift mechanism, and instrument cluster. It enables the execution of key functions such as motor acceleration, deceleration, braking, and parking through the gearshift transmission mechanism. The test panel allows measurement of the drive motor’s circuit signal characteristics, providing a comprehensive demonstration of the motor control system’s structure and operation. Designed for ease of use, safety, and reliability, this training platform delivers an optimal hands-on learning experience for students.

- Motor Type: Permanent Magnet Synchronous Motor (PMSM)

- Power Ratings: 80 kW (continuous), 160 kW (peak)

- Torque Performance: 160N·m to 310N·m with regenerative braking

- Integrated Inverter: Converts DC battery power into AC for motor operation

- Drive Modes: Analysis of Eco, Normal, and Sport driving modes

The equipment frame is a one-piece molded panel frame made of sheet metal. The measuring panel is constructed from a 4mm aluminum-plastic plate, featuring a UV-sprayed surface that prevents fading. Designed with ergonomics in mind, the operation panel ensures ease of use and convenience for students.

Main Components: The equipment includes an original electric permanent magnet synchronous drive motor assembly, transmission shaft, steering knuckle assembly, electronic parking system, cooling system, brake pedal, accelerator pedal, gearshift mechanism, instrument cluster, engine start/stop switch, and measuring panel.

Diagnostic Capabilities: The drive motor training platform is equipped with detection terminals, allowing students to analyze circuit signal characteristics using a multimeter and an oscilloscope.

Real-Time Measurement: The measuring panel features a digital voltmeter that displays signal voltage in real time, enabling students to analyze electrical signals effectively.

Fault Diagnosis: Students can read and clear fault codes in the motor control system, as well as access dynamic data flow, parameter settings, and other diagnostic functions using a specialized decoder for new energy vehicles.

This training platform provides a hands-on learning experience, allowing students to develop practical skills in motor diagnostics and control system analysis.

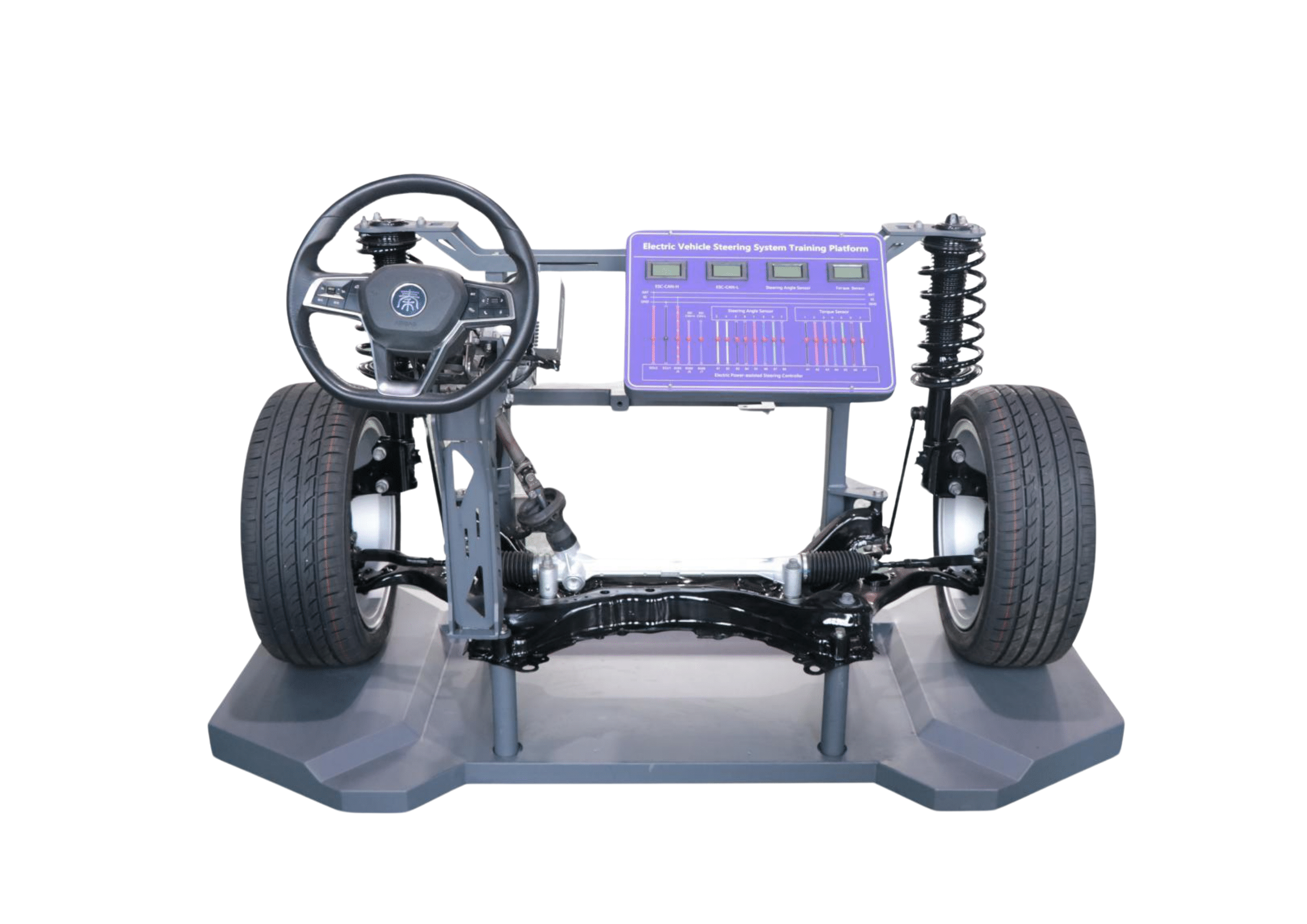

Equipment 3 : BYD Qin EV Steering System Training Platform.

The equipment features a BYD Qin EV rack and an electric power steering (EPS) system, including the front axle, front suspension, steering wheel, transmission mechanism, power motor, and drive wheel assembly. It accurately simulates the connection, control relationships, installation positions, and operating parameters of the core components within an EV EPS system, providing a realistic and practical training experience.

- EPS System: Original EPS system from BYD Qin EV

- Power Supply: 12V DC ensuring smooth and reliable steering

- Digital Torque Monitoring: Real-time performance analysis

- Diagnostic Tools: Fault code reading and clearing capabilities

- Steering Modes: Adaptive learning of Comfort, Normal, and Sport settings

Robust Construction: The equipment frame is made using a sheet metal process for durability and stability. The measuring panel consists of a 2mm bent iron plate with a high-quality sprayed coating that resists fading. Designed with ergonomics in mind, the operation panel ensures ease of use and comfort for students.

Key Components: The system includes an original steering gear, front suspension assembly, steering wheel, and measuring panel, providing a realistic and comprehensive training setup.

Advanced Diagnostics: The power steering training platform is equipped with detection terminals, allowing students to analyze circuit signal characteristics using multimeters and oscilloscopes for hands-on learning.

Real-Time Measurement: The measuring panel features a digital voltmeter that displays signal voltages in real time, making it easier for students to monitor and analyze electrical signals.

Fault Diagnosis and Parameter Settings: Students can read and clear fault codes, monitor dynamic data flow, and adjust parameters on the steering controller using a specialized decoder for new energy vehicles.

This training platform offers a safe, efficient, and interactive learning experience, helping students develop practical skills in power steering system diagnostics and control.

Equipment 4 : BYD Qin EV Air Conditioning System Training Platform.

The equipment is derived from the original BYD Qin EV's automatic air conditioning and heating system after disassembly and redevelopment. It intuitively showcases the connection and control relationships between the core components of the EV’s air conditioning and heating system, along with their installation positions and operating parameters.

- Climate Control System: Original BYD Qin EV HVAC system

- Monitoring: Real-time system operation analysis

- Fault Simulation: Interactive diagnostics and repair features

- Energy Efficiency: Sustainable cooling and heating analysis

- Heat Pump Integration: Study of energy-saving heating systems

Robust Construction: The equipment frame is an integrally molded panel frame made of sheet metal. The measuring panel is an 8mm aluminum-plastic plate, featuring a UV spraying process that prevents fading. Designed with ergonomics in mind, the equipment operation panel ensures ease of use for students.

Main Components: The main components of the equipment include the original electric compressor, air conditioning evaporator assembly, PTC heater, condenser assembly, low-voltage battery, air conditioning operation panel, digital voltmeter, and more.

Diagnostics: The air conditioning system training platform is equipped with diagnostic terminals, allowing students to analyze circuit signal characteristics using a multimeter and an oscilloscope.

Real-Time Measurement: The measuring panel includes a digital voltmeter that provides real-time signal voltage display, enabling students to effectively analyze voltage variations.

Fault Detection: Students can use a specialized decoder for new energy vehicles to read and clear fault codes, monitor dynamic data flow, set parameters, and perform other diagnostic functions.

Equipment 5 : BYD Qin EV Electrical Appliance Training Platform.

This training platform is built using the physical components of the lighting and comfort systems from the BYD Qin EV. It primarily consists of fundamental modules such as combined lighting, a stereo system, an electric wiper, an electric rear-view mirror, a latch, and an electric glass lifter. Each module features original vehicle components that function according to their working principles, completing a full operational cycle.

Designed for teaching and training in new energy courses, this platform is ideal for secondary and higher vocational colleges as well as training institutions. It enables students to understand, operate, and master the structure and working principles of an EV. With its user-friendly design, safety, and reliability, the platform ensures an optimal hands-on learning experience for students.

- Electronic Modules: BYD Qin EV electronic control components

- Circuit Testing: Integrated circuit fault diagnosis tools

- Voltage Monitoring: Real-time voltage and signal analysis

- Hands-on Training: Networking and infotainment system troubleshooting

- Communication Protocols: Study of CAN and LIN bus systems

The equipment frame is an integrally molded panel frame made of sheet metal. The measuring panel is made of a 4mm aluminum-plastic plate with a UV spraying process that prevents fading. Designed with ergonomics in mind, the equipment operation panel ensures ease of use for students.

The main components of the equipment include the original headlamp assembly, glass lift, light controller, rearview mirror, and reading lamp.

The vehicle electrical appliance training platform is equipped with diagnostic terminals, allowing students to analyze circuit signal characteristics using a multimeter and an oscilloscope.

The measuring panel features a digital voltmeter that provides real-time signal voltage display, enabling students to effectively analyze voltage variations.

Please submit your inquiry Submit Inquiry and download a copy of the product flyer by clicking Download Flyer