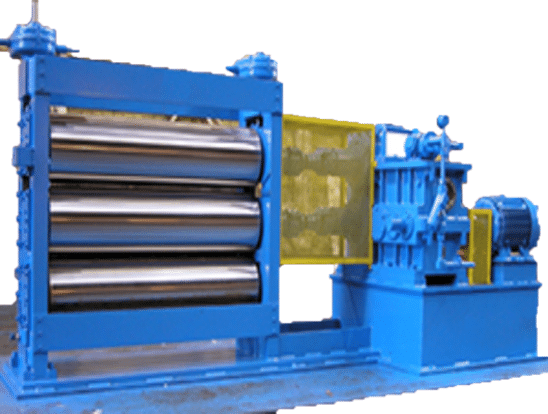

- Roughing mill- The roughing mill consists of usually one or two roughing stands.

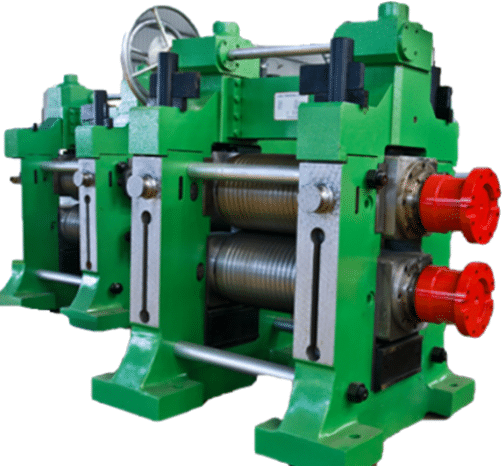

- Intermediate mill- Billet enter from roughing mill.

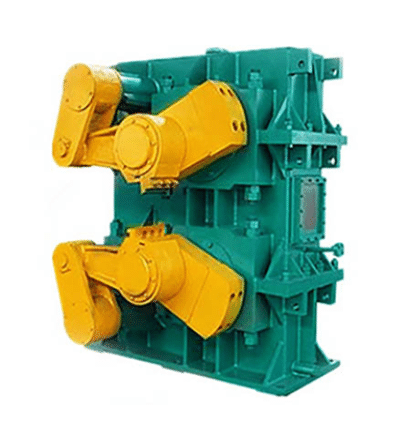

- Finishing mill- Finishing mill consist of more than three stands and pretty much finished product

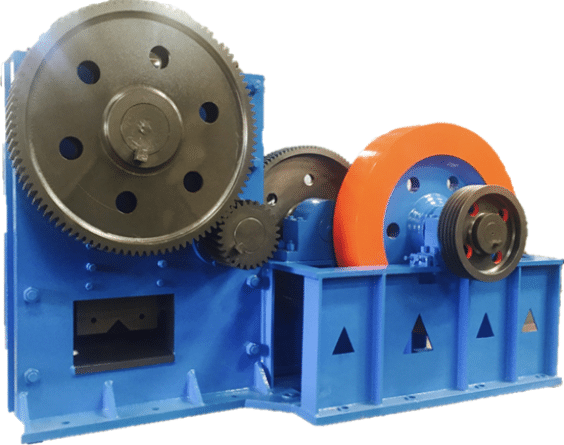

Rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness and to make the thickness uniform. Most steel mills have rolling mill divisions that convert the semi-finished casting products into finished products.