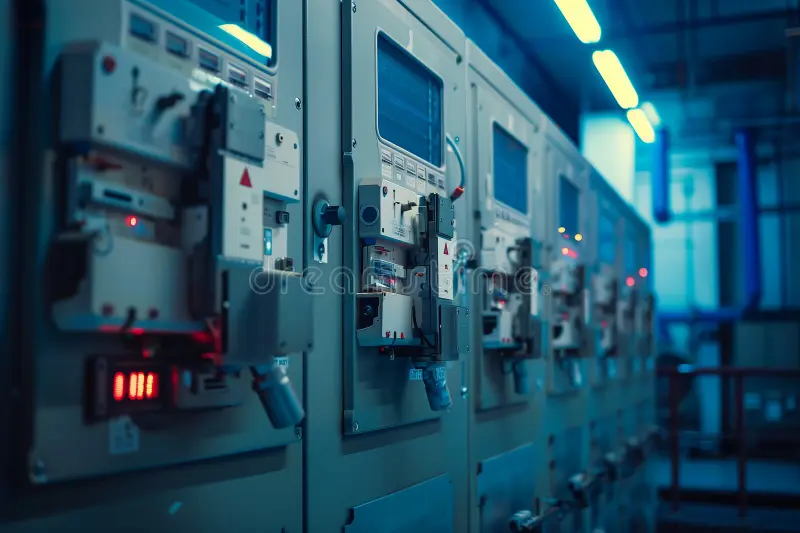

iEngineering specializes in high voltage (HV) panel design, production, and supply services tailored for the Oceania and Pacific regions. Our commitment to quality ensures that clients receive the highest standard of goods at competitive prices. Our team of experts rigorously analyzes various factors to ensure the reliability and efficiency of our HV panels. Key elements of our design process include a comprehensive load flow study to assess electrical demands, as well as detailed calculations of fault levels to guarantee safety and compliance with industry standards.

To enhance the performance and safety of our HV panels, we meticulously select and size the appropriate equipment, creating reports based on these design considerations. We also focus on finalizing the load list and transformer sizes to match specific project requirements. Our designs include single-line diagrams of switchgears and Motor Control Centers (MCCs), alongside control schematics that provide clear guidance for operation and maintenance. By incorporating these critical features, we ensure that our HV panels meet the diverse needs of our clients in the region

Furthermore, our design services extend to the electrical layouts of MCC enclosures, substations, and control enclosures, ensuring a coherent integration of all components. We prepare detailed cable trench and tray layouts, including necessary details and a Bill of Materials (BOM) to streamline project implementation. Our expertise also encompasses earthing calculations, lightning protection measures, and the preparation of PLC architecture diagrams and I/O lists. With a comprehensive cable schedule and interconnection diagrams, along with precise relay setting calculations, iEngineering delivers high-quality, reliable HV panel solutions that are designed to meet the rigorous demands of modern electrical systems.