The economic analysis of a Battery Energy Storage System (BESS) project reveals a positive expected net present value, indicating its financial viability. A key factor influencing this assessment is the round-trip efficiency, which accounts for energy losses during power conversions and parasitic loads, such as electronics, heating and cooling, and pumping. Among various energy storage options, lithium-ion batteries stand out with the highest efficiency rates, ranging from 87% to 94%. This high efficiency contributes significantly to the overall cost-effectiveness of the energy storage system, making it an attractive choice for both grid applications and renewable energy integration.

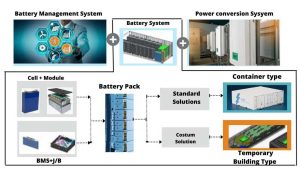

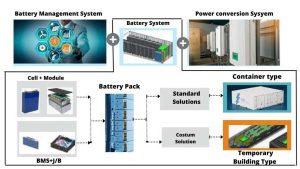

Our approach to BESS design includes the development of reliable algorithms and mathematical models integrated into the Battery Management System (BMS) software. These tools enable accurate estimation of battery state and characteristics, optimizing energy management throughout the system's operational lifecycle. Furthermore, we focus on ensuring rapid response times for the BESS, allowing it to transition from an idle state to full power seamlessly. This capability is essential for providing energy to the electricity grid or renewable power sources, especially during periods of high demand.

Additionally, the performance of the BESS is characterized by various metrics, including ramp rate, output energy density, duration of use during peak and non-peak hours, operational lifetime, and cycle. The sizing of the BESS is critical, tailored to the power converter capacity (measured in megawatts) for grid applications, while also considering the power storage capacity (measured in megawatt-hours) for other uses. By strategically addressing these factors, we enhance the effectiveness and reliability of BESS solutions, aligning them with the needs of modern energy systems.