- Uniform Temperature Distribution

- Overheat protection and thermostat control

- Suitable for various applications, adjustable settings

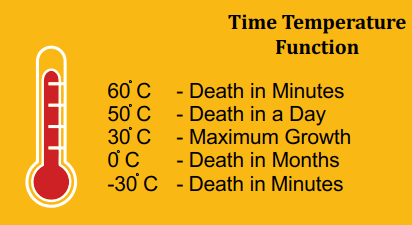

Time Temperature Function

The time and temperature required for the death of insects in a fumigation machine heating process can vary depending on several factors, including the type of insect, its life stage, and the specific fumigation method being used. Different insects have varying tolerance levels to heat, so there is no one-size-fits-all answer.

Heat treatment for insect control typically involves raising the temperature to a level that is lethal for the target pests while avoiding damage to the treated space or its contents. Commonly, temperatures in the range of (60°C to -30°C) are used for insect heat treatments. At the maximum of 60°C and -30°C the insects die in minutes, at 50°C it takes a day for the insects to die, and 30°C is the suitable temperature for the growth of insects. Whereas at 0°C the insects take months to be killed.

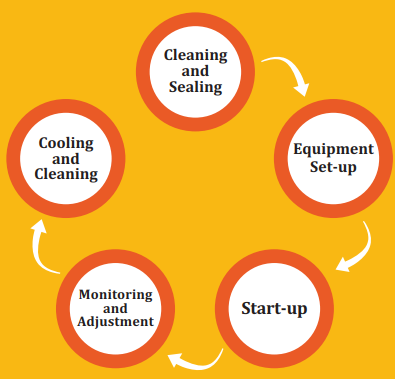

Process

Thoroughly cleanse the area to eliminate any dirt, debris, or residues that could disrupt the fumigation process. Give extra care to spots where pests tend to conceal themselves or lay eggs.

Maintain and elevate the temperature inside the manufacturing facility to a range of 50°C to 60°C for a duration of 24 to 48 hours.

Applications :-

- Food Sectors: Including food processing, farming, mills, and bakeries.

- Animal Food Sectors: Catering to both pet food and animal feed industries.

- Bed Bugs: Providing effective solutions for residential properties, dormitories, and public institutions.

- Hospitality Industry: Serving hotels, motels, and youth hostels with tailored pest control services.

- Travel Industry: Offering solutions for trains, airplanes, and other vehicles to ensure pest-free environments.

- Non-food Sectors: Serving diverse industries such as the tobacco industry, textile industry, and retail stores.